Farming is as much about precision and knowledge as it is about hard work. For those who spend their days in the fields, ensuring that their equipment runs smoothly is crucial to maintaining productivity. One essential tool that many farmers rely on is the John Deere 335 Baler. Today, we’ll demystify the John Deere 335 Baler chain diagram, unpack its components, and explore how you can leverage this understanding for optimal efficiency. Whether you’re a farmer, machinery enthusiast, or AgTech innovator, this comprehensive guide will equip you with the insights you need.

Understanding the Importance of Baler Chains

Why Baler Chains Matter

The baler chain is a fundamental component of your John Deere 335 Baler. It ensures the synchronized movement of different parts, contributing to the efficient operation of the baler. Without well-maintained chains, your baler could face frequent breakdowns, leading to downtime and productivity loss.

The Role of Chains in Machinery

Chains in farming equipment like balers are integral for transferring motion and energy. In the John Deere 335, they help in the rolling and compressing processes, enabling the formation of uniform bales. Therefore, understanding the chain diagram helps in troubleshooting and maintaining the machine.

Common Issues with Baler Chains

Chains can wear out over time, leading to issues like slippage, breakage, and uneven bale formation. Identifying these problems early on through regular inspection can save time and money. Knowing your way around the chain diagram can make these inspections more effective.

Decoding the John Deere 335 Baler Chain Diagram

What the Diagram Shows

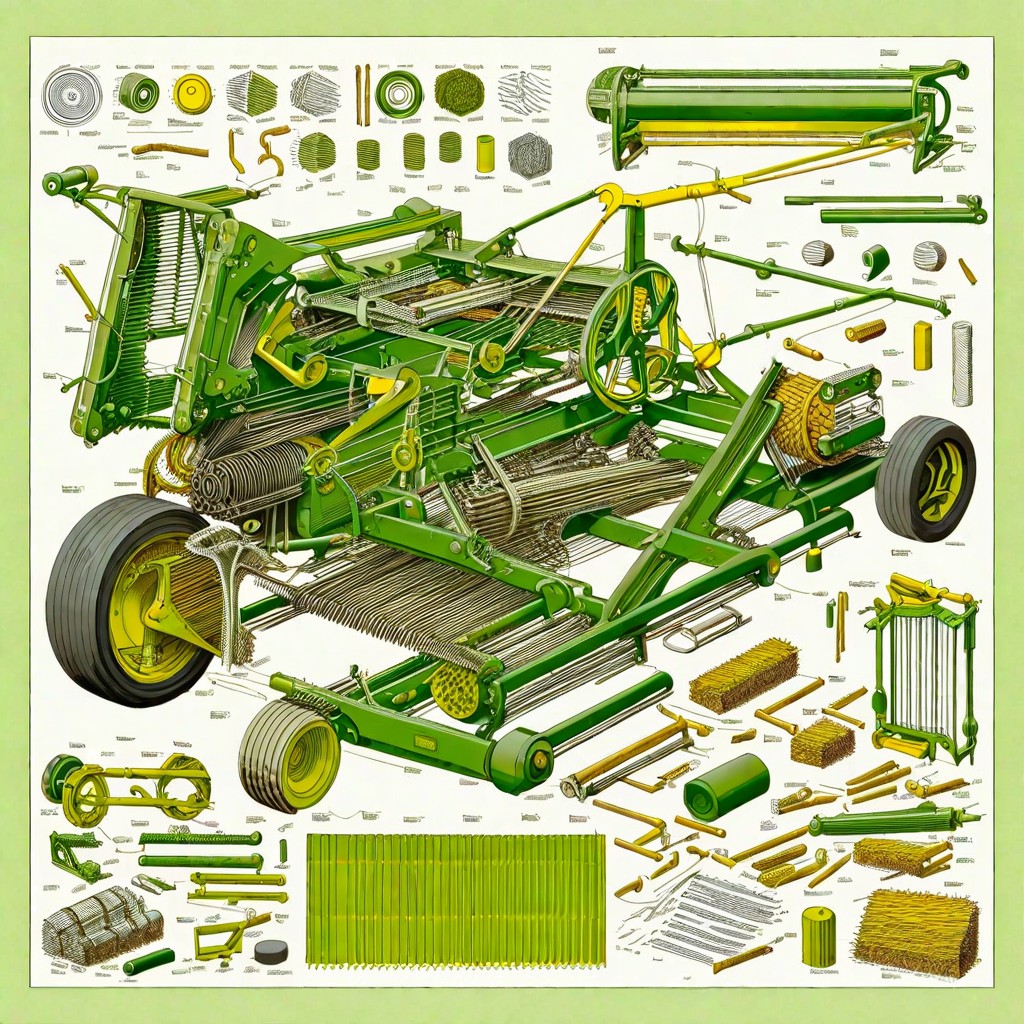

The John Deere 335 Baler chain diagram illustrates the layout and connections of various chains within the baler. It highlights how each chain interacts with other components, providing a roadmap for troubleshooting and maintenance.

Key Components Highlighted

The diagram typically marks essential parts such as the drive chains, tensioners, sprockets, and rollers. Understanding these components and their placement can aid in efficient repairs and replacements.

Reading the Diagram

Reading the chain diagram involves following each chain from its starting point to its end. Note the direction of movement and the parts it connects. This clarity helps in pinpointing any issues and understanding how each part contributes to the overall function.

Step-by-Step Guide to Inspecting Your Baler Chains

Preparing for Inspection

Before you start, ensure the baler is switched off and safely positioned. Gather necessary tools like wrenches, gloves, and the John Deere 335 Baler chain diagram for reference.

Inspecting for Wear and Tear

Check each chain for signs of wear, such as rust, elongation, or broken links. Compare what you see with the conditions shown in the chain diagram. Pay special attention to high-stress areas indicated in the diagram.

Lubricating and Adjusting Chains

Proper lubrication reduces wear and extends the lifespan of the chains. Follow the specifications in the maintenance manual. Adjust the chain tension according to the diagram to avoid slippage and ensure smooth operation.

The Benefits of Regular Chain Maintenance

Prolonging Equipment Life

Regular chain maintenance based on the John Deere 335 Baler chain diagram can significantly extend the life of your equipment. Proper care prevents premature wear and costly repairs.

Enhancing Baler Performance

Well-maintained chains ensure that your baler operates at peak efficiency, producing consistent and high-quality bales. This reliability translates into better productivity and reduced downtime.

Cost Savings

By preventing major breakdowns through regular maintenance, you save on expensive repairs and replacement parts. This proactive approach is more cost-effective in the long run.

Troubleshooting Common Chain Issues

Chain Slippage

If you notice chain slippage, refer to the diagram to check the tension and alignment. Misaligned chains often cause slippage. Adjustments should be made according to the specified parameters in the diagram.

Broken Links

Broken links can halt operations. Identify the broken section using the chain diagram and replace it with a new link. Ensure that the new link matches the specifications provided in the diagram.

Uneven Bale Formation

Uneven bale formation might indicate issues with chain synchronization. Use the diagram to check the alignment and tension of all chains involved in the baling process. Make necessary adjustments to restore balance.

How to Source John Deere Baler Parts Online

Reliable Online Stores

Finding reliable sources for John Deere 335 Baler parts is crucial. Websites like [insert reputable sites] offer genuine parts that match the specifications in your diagram.

Checking Compatibility

Ensure that the parts you order are compatible with your specific model. Cross-reference with the John Deere 335 Baler chain diagram to confirm compatibility before making a purchase.

Dealing with Counterfeit Parts

Be cautious of counterfeit parts that may not meet the required standards. Always buy from reputable dealers and verify the authenticity of the parts against the specifications in your diagram.

Using the John Deere 335 375 385 435 Service Repair Manual

Comprehensive Guide

The John Deere 335 375 385 435 Service Repair Manual is an invaluable resource. It provides detailed instructions and diagrams, including the chain diagram, to assist in repairs and maintenance.

Step-by-Step Instructions

Follow the step-by-step instructions in the manual for accurate repairs. The diagrams offer visual guidance, making complex procedures easier to understand and execute.

Enhanced DIY Repairs

For those who prefer DIY repairs, the manual offers the knowledge needed to handle most issues. With the chain diagram at hand, even intricate repairs become manageable.

Leveraging Technology for Maintenance

Digital Diagrams

Digital versions of the John Deere 335 Baler chain diagram are available online. These can be accessed on mobile devices, offering convenience and ease of use during field inspections.

Maintenance Apps

Various maintenance apps can store and organize your equipment’s documentation, including the chain diagram. These apps provide reminders for scheduled maintenance, ensuring you never miss an inspection.

Online Communities

Join online forums and communities where farmers and machinery enthusiasts share tips and experiences. These platforms can offer additional insights into using the chain diagram effectively.

Expert Tips for Optimal Use of Your Baler

Regular Inspections

Conduct regular inspections using the chain diagram to identify potential issues early. This proactive approach minimizes downtime and enhances overall efficiency.

Training and Knowledge Sharing

Train your team on how to read and use the chain diagram. Knowledge sharing ensures that everyone understands the importance of proper maintenance and can handle minor repairs.

Staying Updated

Keep abreast of the latest advancements in baler technology. Updates and new diagrams may be released, offering improved guidance and efficiency.

Conclusion

Understanding and utilizing the John Deere 335 Baler chain diagram is essential for maintaining the efficiency and longevity of your equipment. Regular inspections, proper maintenance, and leveraging expert resources like the service repair manual can significantly enhance your baler’s performance. By taking these steps, you ensure that your operations remain smooth, productive, and cost-effective.

For those looking to explore further, consider connecting with online communities or investing in digital tools to streamline your maintenance processes. Your baler’s optimal performance is just a diagram away!

By mastering the John Deere 335 Baler chain diagram, you’re not just fixing machinery—you’re setting the foundation for a more efficient and productive farming operation. Happy baling!